Sewing machines are essential tools for those who love to sew, whether for fun or professionally. However, like any other mechanical device, sewing machines can encounter problems that may disrupt your sewing projects. Understanding common sewing machine issues and their solutions can save you time and frustration. Let’s delve into some of the most frequent problems you may face while sewing and how to address them effectively.

**Thread Breakage**

One of the most common issues that sewers encounter is thread breakage. This problem can be caused by a variety of factors, such as using the wrong type of thread, improper threading of the machine, or a dull needle. To address thread breakage, start by ensuring you are using the correct thread for your project and that the machine is threaded correctly. Additionally, make sure to replace your needle regularly, as a dull needle can cause thread breakage.

**Uneven Stitches**

Uneven stitches can be frustrating and can ruin the appearance of your sewing project. This issue is often caused by improper tension settings on the sewing machine. To fix uneven stitches, start by checking the tension settings on your machine. Adjust the tension dial gradually until the stitches are even on both sides of the fabric. It may take some trial and error to find the correct tension setting for your specific project.

**Skipped Stitches**

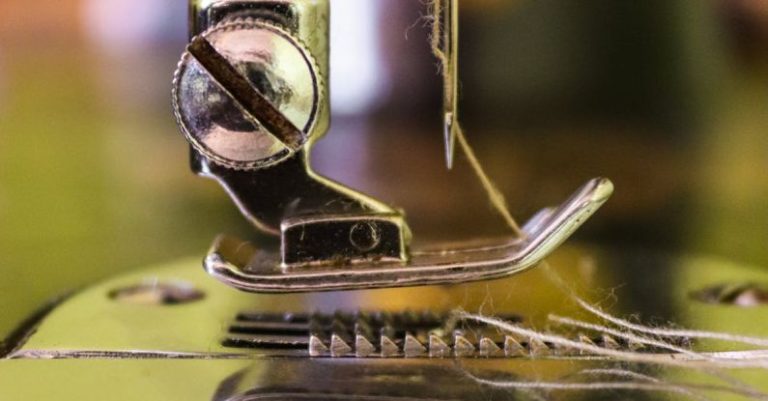

Skipped stitches occur when the sewing machine fails to catch the bobbin thread, resulting in gaps in the stitching. This problem can be caused by a variety of factors, including a bent needle, incorrect needle size for the fabric, or a dirty bobbin case. To fix skipped stitches, start by replacing the needle with a new, straight needle that is appropriate for the fabric you are sewing. Additionally, make sure the bobbin case is clean and free of lint and debris.

**Machine Jamming**

Another common issue that sewers may encounter is the machine jamming or getting stuck while sewing. This can be caused by various factors, such as a tangled bobbin thread, incorrect threading of the machine, or a buildup of lint in the bobbin area. To resolve a jammed sewing machine, start by removing the fabric and checking the bobbin area for any tangles or lint. Clean the bobbin case and rethread the machine, making sure the thread is feeding smoothly.

**Noisy Operation**

If your sewing machine is making more noise than usual, it could be a sign of a problem. Noisy operation can be caused by a variety of issues, such as a loose screw, a misaligned part, or lack of lubrication. To address a noisy sewing machine, start by checking for any loose screws or parts and tightening them as needed. Additionally, make sure the machine is properly lubricated according to the manufacturer’s instructions.

**Fabric Puckering**

Fabric puckering occurs when the fabric gathers or wrinkles while sewing, resulting in an unsightly finish. This issue can be caused by incorrect tension settings, using the wrong type of needle, or sewing too quickly. To prevent fabric puckering, start by adjusting the tension settings on your machine and using the appropriate needle for the fabric you are sewing. Additionally, try sewing at a slower pace to allow the fabric to feed smoothly through the machine.

**Conclusion**

In conclusion, understanding common sewing machine problems and their solutions can help you maintain your machine and ensure smooth sewing projects. By being aware of issues such as thread breakage, uneven stitches, skipped stitches, machine jamming, noisy operation, and fabric puckering, you can troubleshoot problems effectively and keep your sewing machine in good working condition. Remember to regularly clean and maintain your machine to prevent issues from arising and to prolong its lifespan. With these tips in mind, you can tackle any sewing machine problem with confidence and get back to creating beautiful garments and projects.